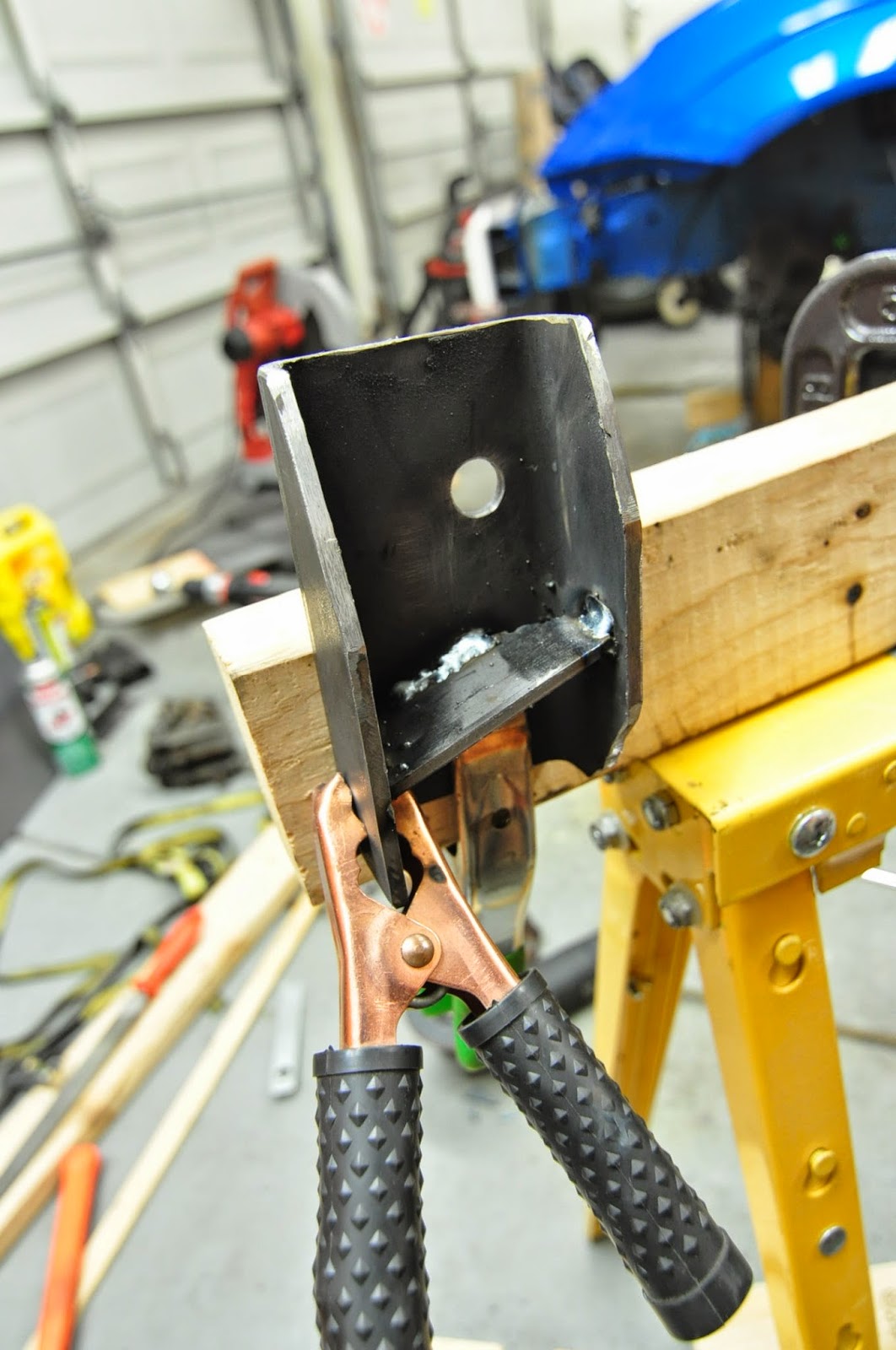

I am planning to heat the corner of that subframe bracket up red hot and stretch it open to the angle I need with an adjustable wrench. I want to see how that works before I cut the other 7 brackets.

In the meantime I started planning out the steering. At the front I have the splined front steer mustang rack. Steering systems for projects like this are pieced together using u-joints and what are called a

DD shafts. I started looking at the right place to break into the focus column to mate the DD shaft with my focus column.

This image shows what would be under the dash:

I started by looking at the top u joint in this image. It can't really be separated without ruining it.

The accordion thing below that I think is what collapses or bends in a wreck so that you aren't impaled. I would like to retain that feature.

Below that is a rod that moves in and out of the accordion thingy freely for about 2 inches of travel. I think this is for tilt steer, but also to accommodate for a little bit of chassis flex that could change the distance of the steering system. A rigid system would put large stresses on the u joints when things flex. On older systems I suspect this function was provided by the rag joint:

(rag joint taken from the mustang. The rubber disk flexes to act like a u joint, and, I think, to absorb a little axial movement)

Below that rod is another inseparable u joint

Below that are some metal pieces that are formed into each other.

If you were looking for a good place to splice in and didn't catch one, neither did I. I really don't want to go welding around in there. I know forces are low, and a weld should be plenty strong. But I just watched "Senna" like 4 times in the last 6 months. The guys at Williams are certainly better at welding steering columns than me...

I looked at the Focus rack to see what I had left behind:

The end of that looks a bit like a DD shaft. Foolish indulgent thoughts, right? Metric focus. English DD shaft... but, I do have a lathe if they are close...

Bottom line: The bottom of the last piece on the column is EXACTLY the right size to receive a 0.75 inch DD shaft and its flats. Should need no lathing. As long as I can snake around things in the engine compartment and interior, everything should plug together end to end with no modification. Thanks Ford!