I laid out the hole locations using a transfer punch onto a notecard.

Then in steel:

Tabs for the alternator. I wanted to make sure that the alternator was mounted really square so that the pulley and belt aren't fighting each other. I tacked the tabs together so I could drill and grind them identical then cut the tacks off:

The original design used this insert so the tabs don't get bent into the alternator. Since my tabs are really short and thick, I retained it:

Corner weld turned out nice:

I still prefer to mig nuts onto things. I tape whatever thread sticks through during welding to avoid spatter making the bolt unremovable.

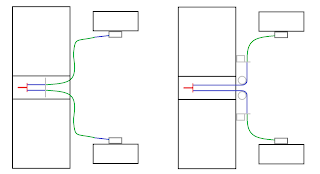

I did a quick FEA because I am worried about vibration. The alternator is heavy and cantilevered, which will tend towards a low natural frequncy. The belt will exert a high force on the bracket which will also drive the frequencies down. Both the 1/rev of the engine, and the 1/rev of the alternator will be strong forcing functions, so consequently I wanted to take a look. I added the gussets you see which drove the first frequency up 50% to get away from the 1/rev for the engine. 1/ rev of the alternator will be hard to avoid. The first mode is basically torsion of the post even though it is .095 wall. You can see I added a tab to share a bolt from the water pump. This did surprisingly little to the first mode, but just seemed like a good move anyway.