My friend Mike Dotsey has always had a real knack for designing things that are clever, and look aesthetically good. I asked him about that years ago, and he said that he thinks the key is to take apart as much stuff as you can to see how other people do things. I took that to heart and have always tried to notice how things are made, and try to guess at or understand how they work. I even take apart my kids' toys if there is some mechanism in it that I can't guess at (I reassemble them. Don't picture me hack sawing the head off their favorite robot while they stand by crying)

On this project working with more modern cars, I have been able to see lots of structural molded plastic parts similar to what I design with at work. It has given me some ideas on how to approach some things. I didn't see anything earth shattering that I never thought of, but here are a few neat parts:

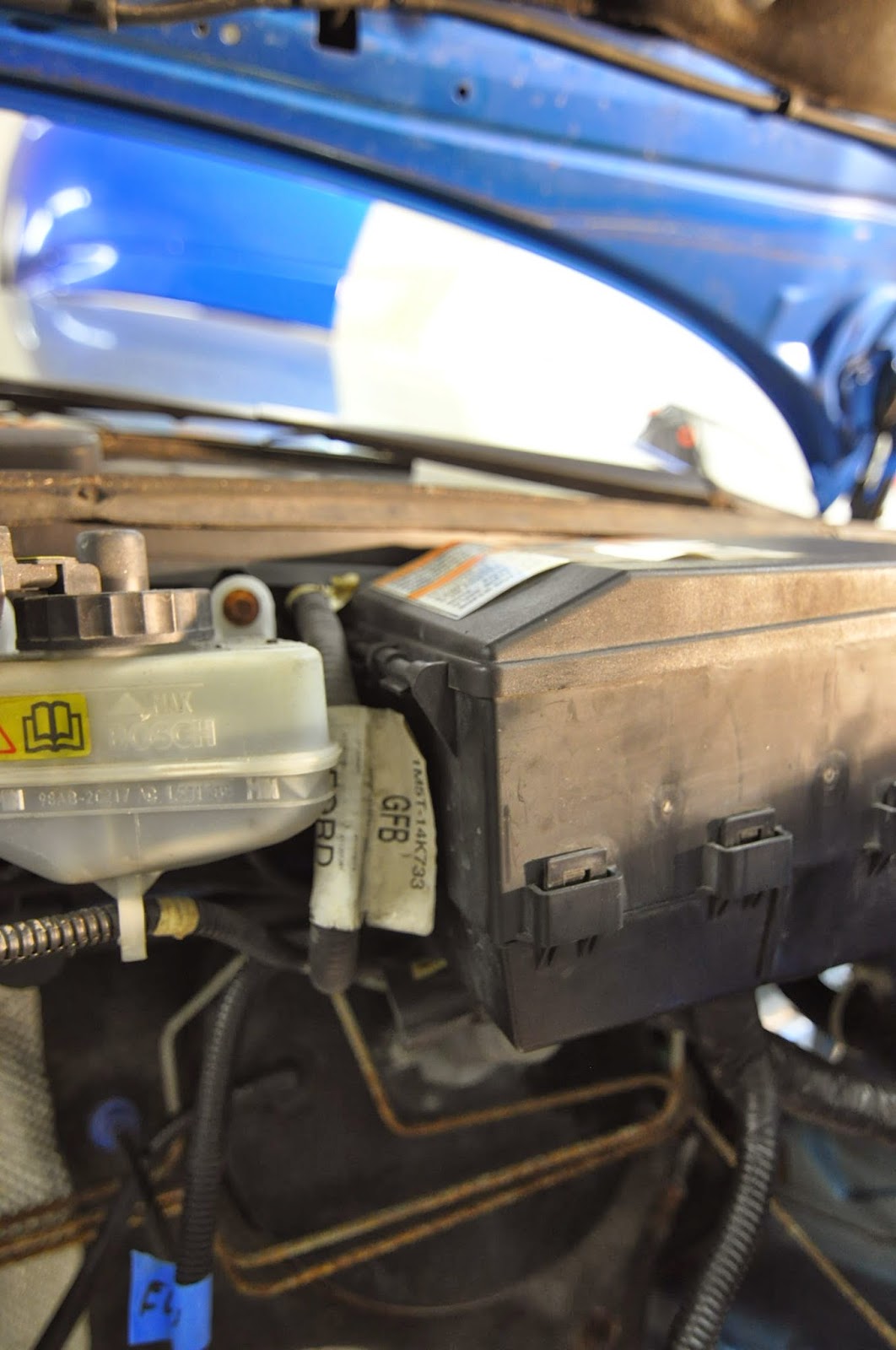

This is a piece that ties the fenders to the bumper, holds the hood shut, and supports cables, wires and the lights. Notice all the egg crate structure underneath. This will be there to help with the overall dimensional stability, but can help buckling performance. I think it is interesting that these are on a 45° bias instead of parallel and perpendicular with the edges. This is probably to add torsional stiffness to an otherwise open section. We are forced to design with mostly open sections because of molding limitations and this is an interesting approach to get back some of what is lost.

(same part) Notice the metal insert on the end of this is bolted on, not molded in. The whole metal insert is bent up from one piece of metal. You can see the large flange on the bolt to avoid high compressive stress in the plastic from the bolt. It seems odd to me that they didn't just mold these features in to save assembly and part count. Maybe flexible metal attachement with large clearance holes is this is how they deal with molding springback, or the fenders flexing.

On the right notice the fingers that hold the hood latch cable. I think that is a clever way to do that. Of course if the customer says, "If the cable comes loose then people die," you would use and adel clamp never look back.

Alright, This one is fairly earth shattering to me. This is a duct that takes air from under the dash, traipses through the console then blows it out in the foot well of the rear seats. There is no way to withdraw a tool from the inside of this, so it is molded in two pieces then somehow fused together. I expect using rf welding, ultrasonic welding or the like. What is interesting is that the inside is smooth with no sharp seam or flash. I don't exactly know what they did. If you do, let me know!

This is a bracket that holds the center arm rest. Nothing too fancy here. Pretty much what I expect. The ribs are not very elegant in this. They are really deep and I think some of them are there just to suppress buckling in their neighbors. I think the deep ribs are like this to make this thing stiff for bending on the minor axis. If that is the case, I would have made at least one that is a straight shot bottom to top. I like the inserts that seem to be popped in after molding. Sort of like the wall hanger you would put in drywall.

Notice the rubber isolation mounts on this which seem to be really low profile. People tend to really cram on shifters so I am surprised that this is a plastic part, and that it is as dainty as it is.

No comments:

Post a Comment