View from above looking down.

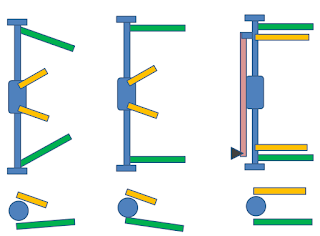

1) Triangulated 4 link

This is what they use on the mustang from the factory. Two lower trailing arms mount to the axle out near the wheel and slope toward the middle of the car. Two upper control arms mount near the differential and slop towards the outside of the car:

Advantages

Since the arms are angled they can carry lateral loads for the car, so you don't need any other links. Also, If this works as is, then I avoid welding brackets on the axle, and avoid making control arms ($$).

Disadvantages

Design math is more complicated. The links are more highly loaded than in other designs. The criss-crossing arms take up a lot of space under the car.

2) Four link with parallel lower link, triangulated uppers

You wouldn't think this changes much, but it is significantly different.

Advantages

This shoots the arms outside the frame rails into the space where the focus trailing arms mounted before. Pretty handy.

Disadvantages

Now the upper links carry all the lateral load.

To ensure we have roll understeer, we must have the lower trailing arms sloping down toward the front of the car, which likely puts the mounts below the scrub line. This also puts the roll center really low, which will decrease the roll stiffness of the chassis.

Also, I will have to remove the brackets which currently hold the lower links and weld on brackets that are pointed the needed direction.

3) Parallel four link plus panhard bar

All links are parallel to the travel direction. A lateral link positions the axle (shown in pink above)

Advantages

This is how solid axle rear suspension for a project like this is often done. Easiest to tune and adjust later. Simple design.

Disadvantages

Car has different roll center for left turns and right turns. Using a watt's link instead fixes this, but significantly complicates things.

The panhard involves the maximum amount of welding and fabrication compared to the options above. It also requires making all the links and buying up to 10 heim joins at ~$50 each.

There are, of course many other suspension choices. I don't want to get into why I didn't choose them, and who knows I may choose one after exhausting my look at these.

I put the axle in place and at ride height to see where things lay with the mustang trailing arms.

This is really encouraging. The jack is holding the original lower link at level. It lands a comfortable distance below the frame rail, which may make bracket fabrication easy, light and strong. The other encouraging bit is that there is about 4 inches clearance to the frame rail in the bump direction. I may be able to avoid notching the rail all together. I would like to have 4-5 inches of travel in both the bump and droop directions.

No comments:

Post a Comment