Started on the control arm brackets. I made a stand to hold the axle at ride height and in the right place. I hacked up some 3/16 box to wrap the frame rail.

Here are the first two pieces of steel:

The frame rails aren't perfect 90° angles so I used my bracket stretching trick from the front rails:

Close up passenger outside after stretching:

Passenger inside pieces after stretching:

After tacking together with the mig I went prime time and did my first welds that will matter with the tig. I am happy with them. Most of my practice was with .062 thick material. This 3/16 was easier to weld. I also have some new electrodes that seem to make the arc easier to control. I did these at 160 amps, which felt a little low.

Monday, December 21, 2015

Friday, November 27, 2015

rear wheel fitment II

I got the studs and spacers from summit. The studs are just barely too long to get behind the hub and use the regular draw them in with lug nut method. So axle out:

Diff cover off. Remove the axle pin retaining bolt:

Axles out and press in the new studs. It takes some attention for them to go in straight enough to not cause problems:

axles back in. new spacers

After:

The wheels go on easily now and can be bolted down. They are right out flush with the edge of the wheel well. If they bump far enough they will probably rub, but for now, I think they are in the right spot. If needed I can always face off the spacer a little in the lathe.

Diff cover off. Remove the axle pin retaining bolt:

Axles out and press in the new studs. It takes some attention for them to go in straight enough to not cause problems:

axles back in. new spacers

After:

The wheels go on easily now and can be bolted down. They are right out flush with the edge of the wheel well. If they bump far enough they will probably rub, but for now, I think they are in the right spot. If needed I can always face off the spacer a little in the lathe.

Friday, November 20, 2015

rear springs part 2

I spent some more time looking at spring and shock selection. As the suspension moves up and down, the angle of the spring changes if it is anything other than straight up and down. I was curious how much spring rate is lost from this travel, as well as how much extra travel length is gained. It is easy to work out:

From there I made a spreadsheet to evaluate real shocks. It turns out for anything much beyond 20° initial angle the spring rate falls very quickly for even modest displacement. I take from this that shocks are inclined to simplify installation, not to gain travel. That said, I do need to angle them. The top area needs to be inside the frame rails (not enough room between rail and tire to be outside, not enough height to be under the rail). If I mount them vertically that far inboard, then there will be too little roll stiffness, and too little roll damping. So I will need to incline them.

I saw a few inexpensive options:

Jegs double adjustable coil overs (currently $186 each) 6.5 inch travel

QA1 Promastar single adjustable (currently $163 each) 6.25 inch travel

QA1 Aluma matic not adjustable (currently $135 each) 5.125 inches travel

I also wanted to look at how long is the shock is as the car sits (ride height). The adjustable shocks are significantly longer. To use a longer shock, I will need to encroach into the truck area and/or mount it lower on the axle which is a potential hazard. While long travel double adjustables would be cool, I just couldn't justify the extra time, expense and sacrifice to space. Most other builds I have found seem to go the same route.

Here is what the spring rate loss is over its full travel as a function of install angle which is TBD. So for example, If I install the shock at a 15° angle from vertical, The spring rate at full bump will be 15% lower than at full droop, and the total axle travel possible is 5.4 inches. This is not including the additional loss of spring rate from the initial angle which is ~ 7%.

From there I made a spreadsheet to evaluate real shocks. It turns out for anything much beyond 20° initial angle the spring rate falls very quickly for even modest displacement. I take from this that shocks are inclined to simplify installation, not to gain travel. That said, I do need to angle them. The top area needs to be inside the frame rails (not enough room between rail and tire to be outside, not enough height to be under the rail). If I mount them vertically that far inboard, then there will be too little roll stiffness, and too little roll damping. So I will need to incline them.

I saw a few inexpensive options:

Jegs double adjustable coil overs (currently $186 each) 6.5 inch travel

QA1 Promastar single adjustable (currently $163 each) 6.25 inch travel

QA1 Aluma matic not adjustable (currently $135 each) 5.125 inches travel

I also wanted to look at how long is the shock is as the car sits (ride height). The adjustable shocks are significantly longer. To use a longer shock, I will need to encroach into the truck area and/or mount it lower on the axle which is a potential hazard. While long travel double adjustables would be cool, I just couldn't justify the extra time, expense and sacrifice to space. Most other builds I have found seem to go the same route.

Here is what the spring rate loss is over its full travel as a function of install angle which is TBD. So for example, If I install the shock at a 15° angle from vertical, The spring rate at full bump will be 15% lower than at full droop, and the total axle travel possible is 5.4 inches. This is not including the additional loss of spring rate from the initial angle which is ~ 7%.

Sunday, November 15, 2015

rear springs part 1

I find surprisingly little about how to calculate spring rates when I read. I thought about it and realized a few things

The amount of droop you have depends entirely on spring rate. The sprung mass at the rear rests on the rear springs. It doesn't matter if you have coil overs that allow you to dial the ride height up and down. If you know your bump travel, then the load at full bump is determined already as well.

"Tune to win" recommended that for a beam axle car you want a minimum of 3 inches bump and 4 droop. If you look at the travel on most inexpensive shock absorbers, the extended to compressed height is significantly less that 7 inches. I conclude from this that the shocks will have to be run at an angle to the axle to get the needed travel as shown on this car:

I never knew why that was done before. This means that spring rate decreases the further you displace, which is the opposite of what you would ideally want.

I also thought about the ratio of sprung to unsprung weight. As you roll over a sudden bump the axle is accelerated upwards. If the body of the car is light or the spring rate is high, the acceleration of the car body upwards is high. I think there is a perception that this affects passenger comfort only. It affects performance as well as it means the cars pitch is constantly changing which affects the suspension geometry, and causes the wheel loads to change dramatically.

If the wheel load is changing dramatically, then the cornering force that can be supported by the rear wheels is suddenly disappearing and reappearing. We have all felt this when cornering in a empty Uhaul truck which has stiff springs.

All this is telling me that I need to have an idea of the sprung and unsprung weights of my car so that I can choose an appropriate travel, and spring rate. I don't want to spend a lot to know this so I bought two bathrooms scales for $8 each. I know a regular car weighs about 3200 lbs. If half that is on the rear, then I have to support about 1600 lbs with two scales that go to 300 lb each. This is easy to do with levers:

The amount of droop you have depends entirely on spring rate. The sprung mass at the rear rests on the rear springs. It doesn't matter if you have coil overs that allow you to dial the ride height up and down. If you know your bump travel, then the load at full bump is determined already as well.

"Tune to win" recommended that for a beam axle car you want a minimum of 3 inches bump and 4 droop. If you look at the travel on most inexpensive shock absorbers, the extended to compressed height is significantly less that 7 inches. I conclude from this that the shocks will have to be run at an angle to the axle to get the needed travel as shown on this car:

I never knew why that was done before. This means that spring rate decreases the further you displace, which is the opposite of what you would ideally want.

I also thought about the ratio of sprung to unsprung weight. As you roll over a sudden bump the axle is accelerated upwards. If the body of the car is light or the spring rate is high, the acceleration of the car body upwards is high. I think there is a perception that this affects passenger comfort only. It affects performance as well as it means the cars pitch is constantly changing which affects the suspension geometry, and causes the wheel loads to change dramatically.

If the wheel load is changing dramatically, then the cornering force that can be supported by the rear wheels is suddenly disappearing and reappearing. We have all felt this when cornering in a empty Uhaul truck which has stiff springs.

All this is telling me that I need to have an idea of the sprung and unsprung weights of my car so that I can choose an appropriate travel, and spring rate. I don't want to spend a lot to know this so I bought two bathrooms scales for $8 each. I know a regular car weighs about 3200 lbs. If half that is on the rear, then I have to support about 1600 lbs with two scales that go to 300 lb each. This is easy to do with levers:

Where Fs is the force on the scale. Fc is the weight of the car. Fj is the force on the jack stand

I put the first side as shown and saw that the car was off both jacks and that the load was much lower than I was expecting. So low that it would be below the scale limit if directly measured:

198 lbf! This seems impossibly light. Add a battery (35 lbf), A fuel cell and gas (75lbf), 20 lbf for all the brackets yet to be done. So about 330 lbs unsprung

Sprung mass:

200 lbf. Add wheels, tires and spacers (75 lbf). So 275 lbf total.

The shocks, springs, control arms, and drive shaft are partly sprung and partly unsprung. If we neglect these for a minute we have 605 lbf for the rear weight. I am concerned, but not surprised at how light the rear end is compared to the front, and concerned at how heavy the axle is compared to the car.

Saturday, November 7, 2015

Rear wheel fitment

I would like to use the stock focus wheels to save cost and maintain the sleeper design. There is an issue here though. The front hub that the wheel slips over is 2.485" diameter. The rear hub is 2.510". Initially I was excited that they are essentially the same, but the wheel that easily plops over the front hub, will not go over the rear.

Originally I noticed that the rear track width between the mustang and the focus was only about an inch different. Since track width is to the center of the contact patch this includes comparing different tire width and wheel back spacing.

I decided to measure the distance between the wheel mounting flanges to get a more objective comparison. I used some old metal stock to make a big caliper, then slid it off and measured the width on the original Focus suspension:

59.125" wide. I noticed that the suspension is at full droop. Accounting for this (control arm is 19" between the pivots and is 23° down from horizontal) puts the focus width at 62.125".

It was more straight forward to measure the mustang axle: 59.5". With the wheels on the axle, not quite fitting over the hub, they are out about .300 per side from seating against the brakes, so at 60.1 inches, they seem 2 inches narrower than stock, quite close to touching the inner wheel well:

So I have 3 options to get the wheel to fit over the hub:

1) Lathe the axle hub

I would only need to take about .010 off the diameter. This would mean removing the axles. I don't know if they would fit in my lathe. I am not wild about this option since this seems like I will end up too narrow

2) Grind out the inside of the wheel

Still concerned that the width will become too narrow for the wheels to clear the wheel well

3) Custom spacer

There are lots of ways this can be done. I think the easiest way is to buy a pair of aluminum spacers and press longer studs into the axle hub. This is cheaper than a wheel adapter, and saves me from the strength and vibration issues that come with that route.

The mustang studs are 1/2 -20 thread. The focus is M12-1.5. The mustang lugnuts do fit in the foocus wheels, so I don't HAVE to change them. It would be nice, so I looked at whether I can get any wheel studs that are long enough and will press into the flange. Just to make sure of the knurl diameter, I knocked one out and measured it:

Originally I noticed that the rear track width between the mustang and the focus was only about an inch different. Since track width is to the center of the contact patch this includes comparing different tire width and wheel back spacing.

I decided to measure the distance between the wheel mounting flanges to get a more objective comparison. I used some old metal stock to make a big caliper, then slid it off and measured the width on the original Focus suspension:

It was more straight forward to measure the mustang axle: 59.5". With the wheels on the axle, not quite fitting over the hub, they are out about .300 per side from seating against the brakes, so at 60.1 inches, they seem 2 inches narrower than stock, quite close to touching the inner wheel well:

So I have 3 options to get the wheel to fit over the hub:

1) Lathe the axle hub

I would only need to take about .010 off the diameter. This would mean removing the axles. I don't know if they would fit in my lathe. I am not wild about this option since this seems like I will end up too narrow

2) Grind out the inside of the wheel

Still concerned that the width will become too narrow for the wheels to clear the wheel well

3) Custom spacer

There are lots of ways this can be done. I think the easiest way is to buy a pair of aluminum spacers and press longer studs into the axle hub. This is cheaper than a wheel adapter, and saves me from the strength and vibration issues that come with that route.

The mustang studs are 1/2 -20 thread. The focus is M12-1.5. The mustang lugnuts do fit in the foocus wheels, so I don't HAVE to change them. It would be nice, so I looked at whether I can get any wheel studs that are long enough and will press into the flange. Just to make sure of the knurl diameter, I knocked one out and measured it:

.615 dia.

Nothing in M12 is even close to that big, so for now I will order long mustang studs. In the future, if I have the differential apart, I can remove the axles and have new smaller holes drilled 45° from the current ones. I don't want to do it by hand now, because with 3 inch long wheel studs and no hub to center the wheel, I will need them to be really straight, and in exactly the right spot.

Thursday, November 5, 2015

rear suspension planning

So there are 3 practical choices for my rear suspension

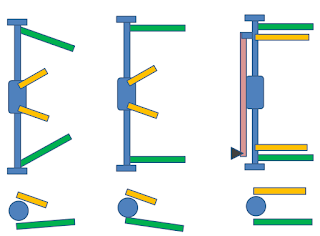

View from above looking down.

1) Triangulated 4 link

This is what they use on the mustang from the factory. Two lower trailing arms mount to the axle out near the wheel and slope toward the middle of the car. Two upper control arms mount near the differential and slop towards the outside of the car:

View from above looking down.

1) Triangulated 4 link

This is what they use on the mustang from the factory. Two lower trailing arms mount to the axle out near the wheel and slope toward the middle of the car. Two upper control arms mount near the differential and slop towards the outside of the car:

Advantages

Since the arms are angled they can carry lateral loads for the car, so you don't need any other links. Also, If this works as is, then I avoid welding brackets on the axle, and avoid making control arms ($$).

Disadvantages

Design math is more complicated. The links are more highly loaded than in other designs. The criss-crossing arms take up a lot of space under the car.

2) Four link with parallel lower link, triangulated uppers

You wouldn't think this changes much, but it is significantly different.

Advantages

This shoots the arms outside the frame rails into the space where the focus trailing arms mounted before. Pretty handy.

Disadvantages

Now the upper links carry all the lateral load.

To ensure we have roll understeer, we must have the lower trailing arms sloping down toward the front of the car, which likely puts the mounts below the scrub line. This also puts the roll center really low, which will decrease the roll stiffness of the chassis.

Also, I will have to remove the brackets which currently hold the lower links and weld on brackets that are pointed the needed direction.

3) Parallel four link plus panhard bar

All links are parallel to the travel direction. A lateral link positions the axle (shown in pink above)

Advantages

This is how solid axle rear suspension for a project like this is often done. Easiest to tune and adjust later. Simple design.

Disadvantages

Car has different roll center for left turns and right turns. Using a watt's link instead fixes this, but significantly complicates things.

The panhard involves the maximum amount of welding and fabrication compared to the options above. It also requires making all the links and buying up to 10 heim joins at ~$50 each.

There are, of course many other suspension choices. I don't want to get into why I didn't choose them, and who knows I may choose one after exhausting my look at these.

I put the axle in place and at ride height to see where things lay with the mustang trailing arms.

This is really encouraging. The jack is holding the original lower link at level. It lands a comfortable distance below the frame rail, which may make bracket fabrication easy, light and strong. The other encouraging bit is that there is about 4 inches clearance to the frame rail in the bump direction. I may be able to avoid notching the rail all together. I would like to have 4-5 inches of travel in both the bump and droop directions.

Wednesday, October 14, 2015

garage engineering

I rearranged some stuff to get the bikes out of the way. I went through my two disassembled cars and made some easy decisions about some parts I won't need and have no resale value. I sold my car ramps, and my catalytic converter, and my mustang (if one could still call it that). The guys who came to get it were super cool. Here it is waiting for it's new owner...

I made some accommodations to make room for the Tig welder. Weelded some horns onto my rack to hold hoses:

Printed this little mig caddy to hold brushes, tips, slips and a can to hold the wire clippings. (took 17 hours to print!)

I made some accommodations to make room for the Tig welder. Weelded some horns onto my rack to hold hoses:

Welded on a bracket to hold the angle grinders:

Looking better:

Welded a piece of old conduit into a tube and to a piece of bar to bolt under my bench and get the craft paper out of the way:

Room to work again... Once I grade the midterms...

Saturday, September 19, 2015

rear suspension overview

So I have been reading about rear suspension design in a few books. To begin, the job of any rear suspension is to:

1) Prevent the wheels from moving left/right or forward/backward relative to the body.

2) Allow the wheels to move up and down together (bump)

3) Allow the wheels to move up down independently of each other (roll)

4) Minimize weight

Since my plan was to build this car from the mustang donor, I committed to a solid axle rear end as opposed to independent rear suspension. I think many people poopoo solid rear suspensions. It isn't really that bad:

1) If the road is smooth, they don't really work worse than IRS.

2) They are cheap.

3) You don't ahve to worry about camber changing, toe changes, and scrub.

As I alluded to previously there is a balance to be had between slapping something together, and making something that works well. Here are a few ways that attention to the design can help:

Roll steer

When the car body rolls in a turn one wheel may move back more than the other or one moves back and one moves forward. This changes the direction that the rear of the car is going.

Left: Roll center below the ground. Notice body moves about roll center

Center: Roll center at axle height

Right. Roll center near CG.

It should be noted that the body will not roll on the paths shown. As soon as the body rolls a small increment, the suspension geometry changes and the location of the roll center changes as well.

The centrifugal force is acting at the car's CG. So the lower the roll center is greater the body roll will be in a turn . Cars counteract the body roll with sway bars, which essentially increase the roll stiffness without raising the bump stiffness.

A higher roll center will cause an increased jacking affect. In other words, the more the body leans, the higher it will get. High roll centers also cause camber to change significantly in roll (although we don't care about this with a solid rear axle!)

1) Prevent the wheels from moving left/right or forward/backward relative to the body.

2) Allow the wheels to move up and down together (bump)

3) Allow the wheels to move up down independently of each other (roll)

4) Minimize weight

Since my plan was to build this car from the mustang donor, I committed to a solid axle rear end as opposed to independent rear suspension. I think many people poopoo solid rear suspensions. It isn't really that bad:

1) If the road is smooth, they don't really work worse than IRS.

2) They are cheap.

3) You don't ahve to worry about camber changing, toe changes, and scrub.

As I alluded to previously there is a balance to be had between slapping something together, and making something that works well. Here are a few ways that attention to the design can help:

Roll steer

When the car body rolls in a turn one wheel may move back more than the other or one moves back and one moves forward. This changes the direction that the rear of the car is going.

Top: No roll steer. Axle pointed in same direction as the body. The line from each wheel intersects the line from the axle indication instant center. This is the point that all four wheels are turning about.

Middle: Roll understeer. The outside wheel moves further forward than the inside wheel when the car body rolls. Although this appears to move the rear of the car into a tighter turn, it actuall moves the instant center out, and makes the car turn on a larger circle. This is stable. Also, note how this took our perfect steering ackerman and turned it into pro ackerman.

Bottom: Roll oversteer. The inside wheel is moves further forward than the outside wheel. This tightened up out turning radius. This is unstable. The car roll made the car turned tighter, which will make the car body roll more, which will make the car turn tighter still, which mill make the body roll more... until you spin. Note that this also creates anti ackerman.

It is not the goal to make a design that has no roll steer for the entire range of suspension travel and roll. I don't even know if it is possible, but if you could you would almost certainly have terrible handling as you abandoned all other design goals. The goal should be to keep roll steer to a minimum, and to sacrifice whatever is needed to be sure we have roll understeer.

Antidive and antilift

If side view instant center for the rear suspension is in line center of gravity then the thrusting force from the wheels will be applied directly to the CG and the car will not squat when accelerating. The flatter the swing arm angle relative to the ground, the larger the moment created by the thrusting wheel force compared to the CG, and the harder the car will squat. Fine for a drag race. You generally want a little squat, and a little dive on braking so that the driver can feel what is going on.

Top: 100% anti squat

Bottom: 0% anti squat. Amount of squat depends on spring rate.

Roll center

If we imagine being aft looking forward. We can imagine that there is a point that the car will roll about.

Center: Roll center at axle height

Right. Roll center near CG.

It should be noted that the body will not roll on the paths shown. As soon as the body rolls a small increment, the suspension geometry changes and the location of the roll center changes as well.

The centrifugal force is acting at the car's CG. So the lower the roll center is greater the body roll will be in a turn . Cars counteract the body roll with sway bars, which essentially increase the roll stiffness without raising the bump stiffness.

A higher roll center will cause an increased jacking affect. In other words, the more the body leans, the higher it will get. High roll centers also cause camber to change significantly in roll (although we don't care about this with a solid rear axle!)

Saturday, September 12, 2015

cobwebs and crickets

A little over 2 months since the last post. Embarrassing. The main reason for this is that we got some attached bicycles to ride around with the kids. They are too big and heavy to disconnect from our bikes and take to the basement after each use, so guess what: they all now live in the last open space in the garage. They make it completely impossible to open any drawers on 4 of 6 tool boxes, impossible to use the lathe, press, or workbench, and they use up the last spot of floor space where I could work. Epic.

As if that wasn't bad enough spacewise, the mustang has finished shedding parts into my garage, and then I got this beauty off CL which is taking up some space I didn't even have:

At this point only the fact that I have a clear goal is separating my garage from that of a hoarder's.

Also school started 2 weeks back and I am teaching a new course in the afternoons. However, my luck is turning. The course I am teaching is a subject I know really well so it hasn't destroyed my free time.

I also finally bought this:

I think we all tend to think that someone who analyzes less than us is a maniac, and someone who analyzes more than we would is too academic for the real world. It is hard to know how much is the right amount. I think this quote sort of helps ground that effort. It makes me think I am doing things about right actually. Although perhaps no matter what one's level of care were, it may make him think that!

I hope to be posting again soon with some rear supsension discussion!

As if that wasn't bad enough spacewise, the mustang has finished shedding parts into my garage, and then I got this beauty off CL which is taking up some space I didn't even have:

At this point only the fact that I have a clear goal is separating my garage from that of a hoarder's.

Also school started 2 weeks back and I am teaching a new course in the afternoons. However, my luck is turning. The course I am teaching is a subject I know really well so it hasn't destroyed my free time.

I also finally bought this:

I wish I had gotten it much sooner. I am starting into the rear suspension design which would have been impossible without this book. I say this already having 4 books on the subject. One of the suspension chapters begins with an awesome quote:

"Figuring the suspension of a car is almost entirely a matter of making useful approximations. It is not an exact science. But neither is it a blind application of rule of thumb principles."

- Maurice Olley 1961I think we all tend to think that someone who analyzes less than us is a maniac, and someone who analyzes more than we would is too academic for the real world. It is hard to know how much is the right amount. I think this quote sort of helps ground that effort. It makes me think I am doing things about right actually. Although perhaps no matter what one's level of care were, it may make him think that!

I hope to be posting again soon with some rear supsension discussion!

Sunday, June 28, 2015

making room for the axle

Pulled out my gas tank with 2 year old gas in it. Drained some, filtered it and ran it in the lawn mower. Seemed to run fine. Put some in my wife's car and the rest fit in gas cans. Glad I didn't have to pour it over the heads of baby bunnies or anything like that.

So I put the axle under the car and slid the wheels on. The spare tire well is in the way as you can see here where the axle is still too low:

Here is the last unmolested area of my car:

Lested:

I wrote down the fender gap before starting this project; 3 inches. Here is the wheels now at 3.5 inches:

Not very visible from the back which is good. I think not using a bright shiny diff cover helps with this.

Saturday, June 27, 2015

focus rear subframe out

back from vacation. Pulled out the focus rear subframe today. It was pretty hard to get out for just 6 bolts, two shocks, 2 ebrake cables, and 2 brake hoses:

Here was a nice surprise:

this is the Mustang brake drum inside the focus wheel... same bolt pattern I think. Which means I won't have to redrill the hubs. If this is right, it may be the first thing that hasn't been the hardest it could be. The studs are larger for the mustang, so I may need to do something creative there.

I pulled out the exhaust and the rest of the heat shielding. Will get some shots under the car once the fuel tank is out.

Here was a nice surprise:

this is the Mustang brake drum inside the focus wheel... same bolt pattern I think. Which means I won't have to redrill the hubs. If this is right, it may be the first thing that hasn't been the hardest it could be. The studs are larger for the mustang, so I may need to do something creative there.

I pulled out the exhaust and the rest of the heat shielding. Will get some shots under the car once the fuel tank is out.

Monday, June 15, 2015

V8 no wheel drive

Here it is. Ready to go nowhere.

Time to get started on the back end. I put the mustang on some harborfreight furniture dollies. This was not the best move. When I was rolling the car around later one of the casters exploded and left the car stranded in the middle of the driveway. I still need a better way to move a wheel-less car around.

Subscribe to:

Posts (Atom)